Build to Print

Quality

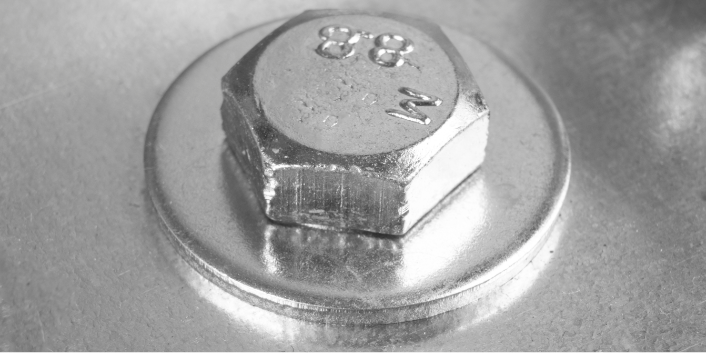

ZHONG JIU is, specialty fastener machine shops in the United States. If it's not in our inventory, we pride ourselves on getting you what you need. Our large supply of blanks, our equipment, and a near non-stop manufacturing schedule allow us to get you what you need when you need it—even custom orders.